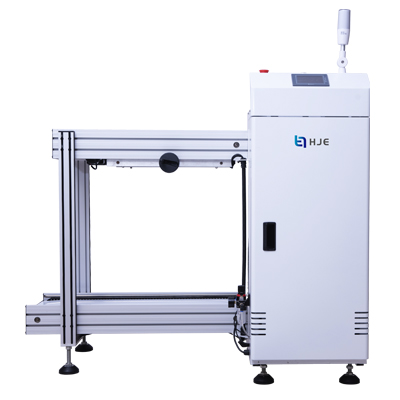

- Robust Construction: Fully steel frame with welded metal plates. The PCB Loader is also finished with high-temperature-resistant spray coating for longevity and unmatched performance.

- Advanced Control System: The PCB Loader features a high-quality Mitsubishi PLC and an intuitive touchscreen interface for ease of use.

- Accurate Material Handling: It has a motor-driven lifting mechanism with transmission via a precision ball screw. Also, the step distance can be set to 10, 20, 30, or 40 mm.

- Secure Material Containers: The PCB Loader has a four-position cylinder that securely holds and moves containers for stable operation.

- Adjustable Board Pushing: The PCB Loader provides smooth, stable movement with adjustable speed settings.

- Safety Features: It is equipped with photoelectric protection and sound & light alarms to ensure safe operation.

- Inline Compatibility: It also supports the standard SMEMA protocol for seamless communication with other machines in production lines.

Specification:

| Model | WIT-PCB250A | WIT-PCB330A | WIT-PCB390A | WIT-PCB460A | WIT-PCB625A |

| Dimension (L×W×H) | 1075×765×1230(mm) | 1210×848×1200(mm) | 1360×925×1224(mm) | 1360×958×1224(mm) | 1484×958×1224(mm) |

| Applicable material frame (L×W×H) | 355×320×563(mm) | 460×400×563(mm) | 535×460×570(mm) | 535×530×570(mm) | 630×530×570(mm) |

| PCB Size (L×W) | 50×50~L350×W250(mm) | 50×50~L460×W330(mm) | 50×50~L530×W390(mm) | 50×50~L530×W460(mm) | 50×50~L625×W460(mm) |

| Air Pressure | 5KGf/cm² | ||||

| Power supply | AC220V 50/60Hz | ||||

| Power | 300W | ||||

| Transport Height | 900±30(mm) | ||||

| PCB Thickness | 0.6-4mm | ||||

| Transport direction | L-R or R-L (optional) | ||||

| Rack Lifting Step | 10,20,30,40(mm) | ||||

| Control Mode | PLC+ Touch Screen | ||||