Everyone needs an SMT equipment maintenance checklist to safeguard their production line, extend the lifespan of their machines, and ensure they deliver consistent product quality. This checklist has to be more than a routine task. It needs to be a structured approach that ensures the efficiency of your production and the quality of your products.

Neglecting preventive measures leads to a spiral of rework, costly repairs, production delays, and numerous other issues! Don’t let minor problems snowball into major defects that compromise your output. Let us teach how to do things right!

In this blog, we will walk you through a comprehensive SMT equipment maintenance checklist, drawn from the insights of industry experts.

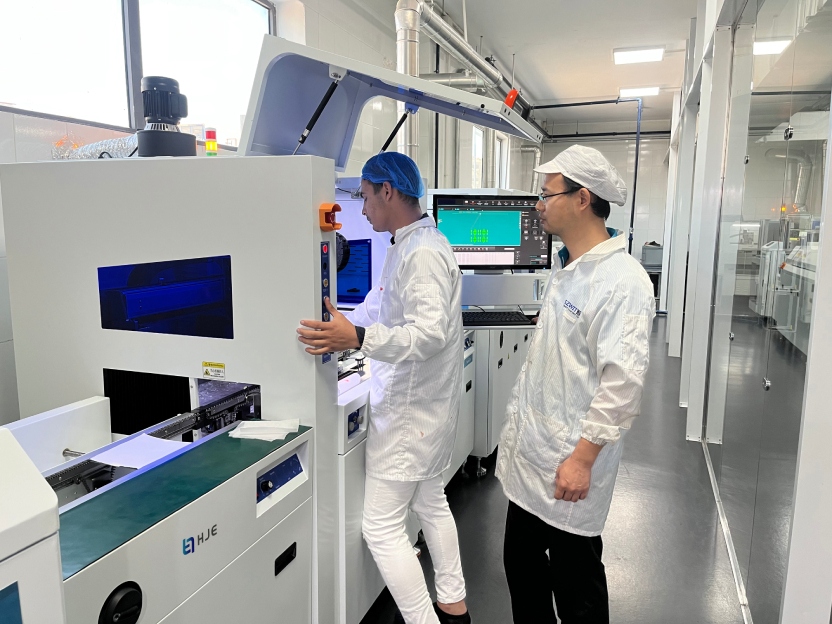

Build a culture of quality and reliability with HJE TECH India PVT. LTD. Keep reading to know more!

SMT Equipment Maintenance Checklist: Preventive Measures

Why Preventive Measures Matter?

Routine preventive care of your SMT machines ensures optimal performance, fewer repair costs, fewer delays and downtime, product inconsistency, no defects and breakdowns, and so much more.

Without a proper SMT equipment maintenance checklist, you can have higher chances of product line breakdown, quality inconsistency, and poor efficiency of equipment.

Reflow oven cleanliness and correct profiling are especially critical: a sealed, residue-free oven holds temperature uniformity and protects solder joint integrity; regular thermal profiling confirms the oven is delivering the expected temperature curve to meet assembly specs.

What are Some Best Practices for SMT Machine Maintenance?

Make sure you store logs of every maintenance checklist you perform. Use a simple standardised form per shift and log the data digitally. Train and empower operators to run the daily checklist and spot early signs of weakness.

Focus on spare parts. Track lead times and stocking levels for high-use items: nozzles, feeder tapes, heaters, and thermocouples. Thermal profiling is crucial; profile any new product or solder paste lot. Small shifts in profile can cause large quality changes.

How to be Safe?

- Maintain a service history log for each machine, that is, date, technician, actions taken and parts used.

- Use PPE when handling hot pots and cleaning chemicals.

Maintain a regular SMT Equipment Maintenance Checklist

Daily

These are fast checks every operator should run before production starts. Visually inspect the line for stray parts, loose tools and foreign objects.

Check ESD humidity controls, inspect nozzles for residue/clogging, and ensure feeders are seated and advancing correctly. For the solder paste printer/stencil, wipe off paste buildup and check the squeegee condition.

Confirm conveyor movement, exhaust functioning and that the oven is warm/stable. For the AOI inspection machine, wipe lenses and viewports; run a quick diagnostic camera check. Ensure belt tracking, sensors and guide rails are free of debris in shuttle conveyors.

Weekly

These are heavier tasks than daily, so needs to be performed by technicians. Get all the nozzle channels, feeder tracks, and pick heads cleaned. Replace any worn-out nozzles.

Clean the reflow oven internally and replace air filters if needed. Confirm fans and heaters show no abnormal vibration or noise.

Inspect shuttle conveyor belts and rollers; lubricate bearings where specified by OEM. Check flux spray uniformity in wave solder machines, and clean filters and inspect spray nozzles for blockages.

Monthly

You need to plan and document every inspection and replacement. Conduct a thorough feeder audit and replace pads or worn springs as necessary.

For your shuttle conveyor machine, check encoder alignment, limit switches, and any shuttle couplings; tighten fasteners. Clean the wave fingers of your wave soldering machine, inspect heaters and thermocouples, and verify pump performance.

Clean the sensors and heat sinks of AOI; check image registration against a known good board.

Annual

For an annual checklist, you need a comprehensive overhaul and calibration. Make sure you do a complete mechanical inspection of the linear guides, lead screws, motor couplings, and emergency stops.

Fully recalibrate the AOI camera and/or optics, keep your SMT machine software updated and do repeatability testing.

For reflow, replace critical thermocouples, perform vendor-recommended service, and revalidate profiles for all product families. Your wave soldering machine requires heater checks and service for the dross removal system.

Why HJE TECH India PVT. LTD.?

Choosing the right professional for SMT equipment and its maintenance matters! You need consistent quality, minimal downtime, and expertise that delivers excellence. Where do you get all that? With HJE TECH India PVT. LTD.

Get in touch with us!

- 10+ years of experience, industry-expert team, and transnational support

- Expertise in SMT equipment, customised solutions, and a preventive approach

- End-to-end services, vast inventory, and quality in everything

Choose reliability. Choose precision. Choose HJE TECH India PVT. LTD.

The Bottom Line

Maintaining your SMT production line does not have to be overwhelming when approached with a structured and disciplined SMT equipment maintenance checklist.

Divide your approach into daily, weekly, monthly, and annual maintenance routines. This way, you prevent unexpected failures, extend the operational life, and ensure consistent production quality.

From shuttle conveyors to wave soldering machines, every piece of equipment requires targeted care to keep performance at peak levels.

Ultimately, a strong maintenance regime is not just about minimising downtime; it is about creating sustainable efficiency, cost savings, and long-term trust in your manufacturing capabilities.

Contact HJE TECH India PVT. LTD. for high-quality services and machines!

Keep Your SMT Machines Reliable: Request Maintenance Today

Protect your investment with HJE TECH India PVT. LTD. Get expert maintenance and high-quality SMT machines. Reduce downtime, increase yield, and extend machine life by partnering with us.

Ensure peak performance of SMT machines with HJE TECH India PVT. LTD. Contact us today!

FAQs on SMT Equipment Maintenance Checklist

How do software updates impact SMT machines?

Software updates can improve machine performance, add new features, and correct operational bugs. Maintaining updated software ensures accuracy, precision, and optimal control.

How can I manage the spare parts?

Maintain an inventory of high-use items, including nozzles, feeder pads, belts, etc. Track consumption and lead times to avoid production delays and ensure timely replacements during preventive maintenance.

Can following a maintenance checklist reduce costs?

Preventive maintenance ensures no equipment failures, unscheduled downtime, rework, costly repairs, and more. It prolongs lifespan, optimises production efficiency, product quality, and emergency repair costs.

What are some common wear parts in SMT machines?

Common wear parts include pick-and-place nozzles, belts, bearings, filters, shuttle conveyor rollers, and more. You need to regularly replace them to prevent downtime and failure.

Disclaimer: The information provided in this content is just for educational purposes and is written by a professional writer. Consult us to know more about SMT machines.