Looking for a magazine unloader for your SMT line? Stick to this guide to know how to choose an SMT magazine unloader for increased productivity and improved product quality.

In the world of electronic manufacturing, precision and efficiency are paramount, and that’s where the magazine unloader comes in, a game-changer for Surface Mount Technology (SMT).

A magazine unloader automates tasks in SMT manufacturing by removing PCBs from conveyors and placing them neatly into the magazine or trays.

Choosing the right magazine unloader significantly impacts an SMT line’s efficiency, productivity, quality, and cost-effectiveness by ensuring a seamless, automated material flow and minimising defects.

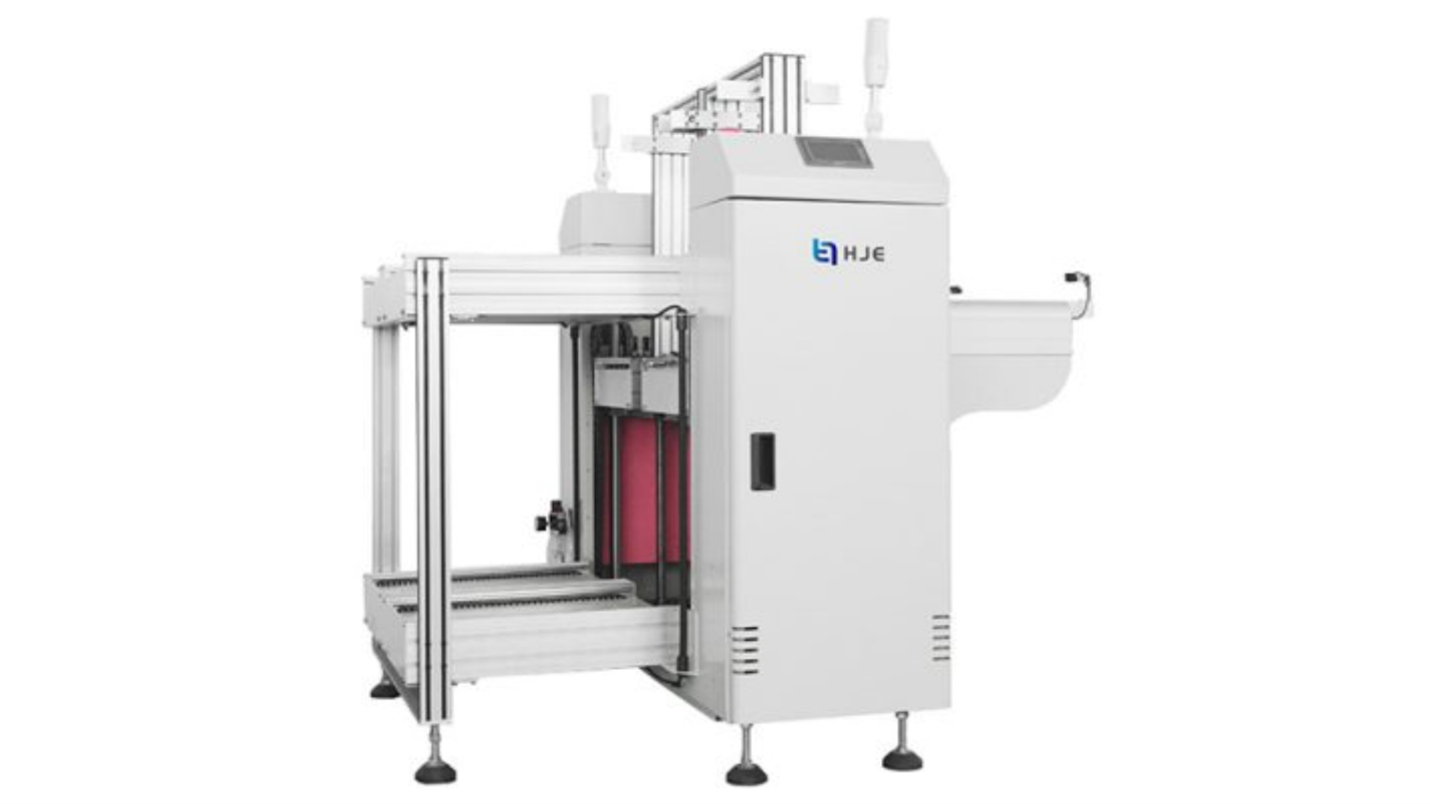

At HJE Tech India Private Limited, we offer comprehensive SMT solutions, including magazine unloader, to ensure precision, quality, and scalability in electronic assembly.

Let’s break it down step by step on how to choose an SMT magazine unloader to reduce labour costs and ensure seamless workflow integration.

Guide on How to Choose an SMT Magazine Unloader: Key Factors

Here are the key factors to consider when choosing the right magazine unloader for your SMT line.

1. PCB Size Compatibility

Every SMT line handles different PCB formats, consumer electronics, LED boards, automotive PCBs, telecom modules, you name it. Before finalising an unloader, verify:

- Minimum and maximum PCB size

- PCB thickness compatibility

- Whether the unloader supports your magazine type (typically 535, 460, or custom sizes)

2. Type of Magazine Used

Different industries rely on different magazine styles:

- Standard SMT PCB magazines: Electronics manufacturing industry

- Aluminium magazines: Aerospace and automotive industry

- Long-format solder-frame magazines: Electronic manufacturing industry

Your unloader must match the exact magazine model your line uses or be adjustable enough to accommodate multiple sizes.

3. Transfer Speed & Line Matching

A common mistake is choosing an unloader with a slower transfer speed than the rest of the SMT line.

Consider these while evaluating:

- Conveyor speed

- Lift motion cycle time

- Buffer capacity

- Indexing accuracy

4. Build Quality & Durability

Don’t underestimate mechanical quality. Magazine unloaders work continuously throughout every shift.

Check for:

- Sturdy aluminium or steel frame

- Smooth ball-screw or belt-driven indexing

- High-quality motors and sensors

- Anti-jam mechanisms

A durable unloader won’t just last long; it will also reduce unplanned downtime.

5. Ease of Operation and Safety

Look for features that make it operator-friendly:

- Intuitive touch interface

- Easy magazine loading

- Safety doors and emergency stop buttons

- Jam detection alarms

When the machine is simple to use, training time drops dramatically.

6. Integration with Upstream Machines

Your unloader must communicate seamlessly with:

- Reflow oven output conveyor

- Inspection systems

- Buffer units

- Pick-and-place lines (if unloading from bare board assembly)

7. Budget, Maintenance, and After-Sales Support

A magazine unloader is a long-term investment. Look at:

- Cost vs. performance

- Maintenance requirements

- Spare parts availability

- After-sales support and warranty

- Local service response time

At HJE Tech India Private Limited, we provide you with PCD Unloaders that help avoid manual touch, reduce labour cost, and increase production efficiency.

Practical Tips When Selecting a Magazine Unloader

Here’s a quick checklist many production managers swear by:

- Map your PCB sizes before choosing a model

- Match the unloader speed to your SMT line throughput

- Confirm SMEMA compatibility

- Prefer adjustable magazine holders

- Ensure the machine height aligns with your upstream equipment

- Ask for demonstration videos or on-site trials

- Verify spare parts availability in India

These small steps save major headaches later.

Why Choose HJE Tech India Private Limited for Magazine Unloader

HJE Tech India Private Limited stands out for its reliability, industry knowledge, and customer-first approach. Here’s what makes a preferred partner:

- Comprehensive SMT Solutions: We offer complete SMT solutions, from magazine loaders/unloaders to conveyors, pick-and-place machines, reflow ovens, and complete SMT line setups.

- Expert Consultation: Our team helps you understand how to choose an SMT magazine unloader based on your specific PCB size, industry, throughput goals, and plant layout.

- Reliable After-Sales Support: HJE Tech provides installation, training, preventive maintenance, and fast service response.

- Quality Machines Tested for Indian Conditions: Our equipment is optimised for India’s diverse manufacturing landscape, whether it’s high-volume consumer electronics or specialised automotive/LED production.

The Bottom Line

Choosing a magazine unloader for your SMT line isn’t just about adding a machine to your production line. It’s about ensuring smooth production, increased productivity, and improved product quality. When you consider PCB size, speed, magazine type, integration needs, and safety, the decision becomes clearer.

Want to upgrade your SMT line? HJE Tech India Private Limited offers comprehensive SMT solutions tailored to your manufacturing needs.

Get in touch with us to improve your manufacturing efficiency and product quality.

FAQs about Choosing an SMT Magazine Unloader

What is the purpose of an SMT magazine unloader?

It collects finished PCBs from the SMT line and stacks them safely into magazines, ensuring a smooth production flow and preventing damage from manual handling.

Can one magazine unloader handle multiple PCB sizes?

Yes, many models come with adjustable magazine brackets and conveyor widths. However, confirm compatibility before purchasing.

How do I know if my unloader is SMEMA compatible?

Your vendor should provide the SMEMA compliance specification. If not, check for standard interface connectors and communication protocols.